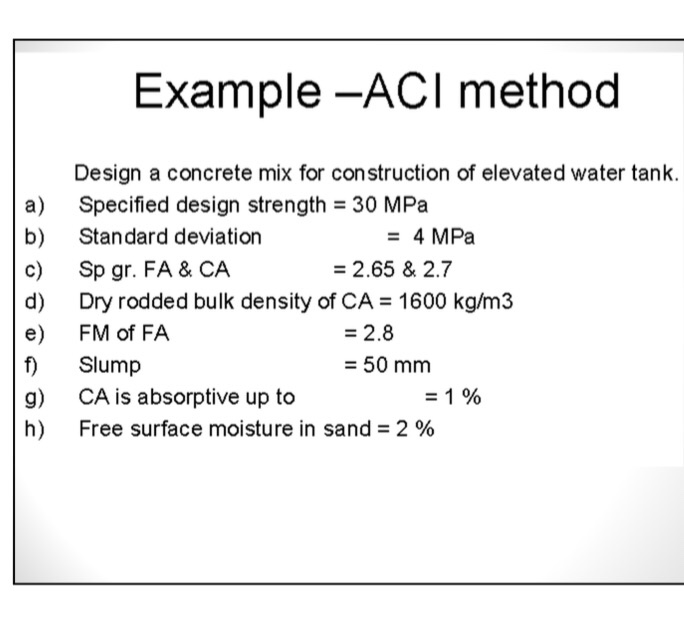

The effect of variation of these input parameters on mix proportions has been studied here with reference to strength attainment in few cases. This video presents a concrete mixture design example by ACI 211. Aci mix design procedure.

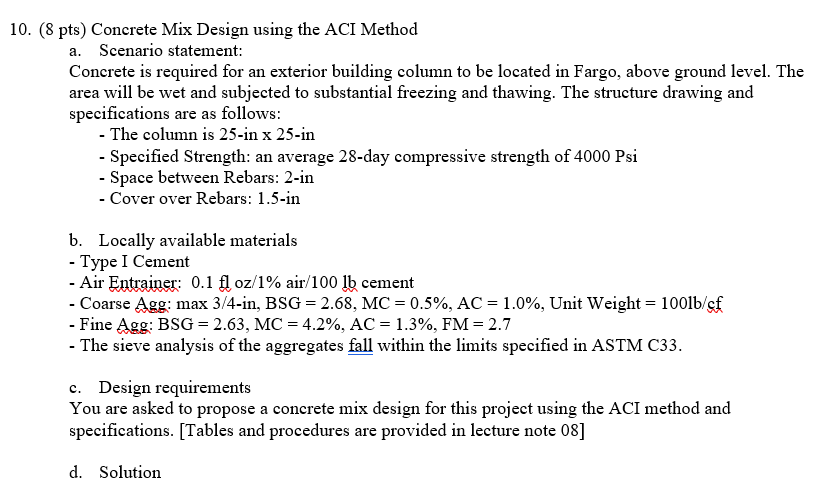

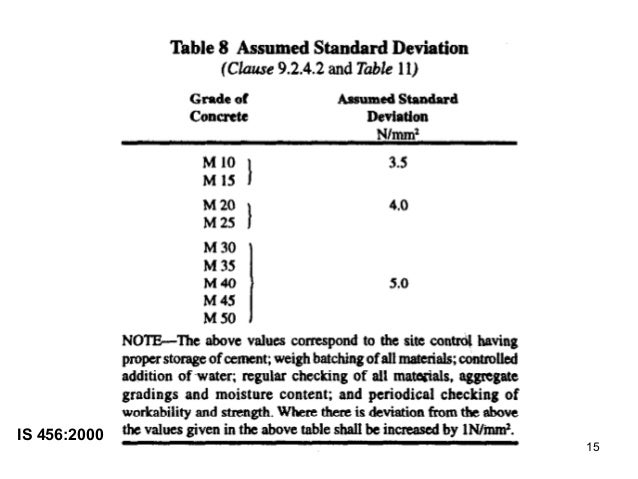

Aci Mix Design Procedure, Choice of maximum size of aggregate Step 3. Concrete mix design procedure as per aci method Yogesh Aggarwal Assistant Professor Paratibha Aggarwal Professor Vaibhav Sharma final year student Department of Civil Engineering NIT Kurukshetra Kurukshetra Haryana Concrete is a widely used building material. 6Cement content 7Coarse aggregate content. Selection of water cement ratio.

Aci Tables For Concrete Mix Design From goood-design.blogspot.com

Aci Tables For Concrete Mix Design From goood-design.blogspot.com

Aci Method Of Concrete Mix Design. 9Adjustments for aggregate moisture 1The required target average compressive strength. Applies equally well with more or less identical procedure to rounded or angular aggregate. Concrete Mix Design Calculation.

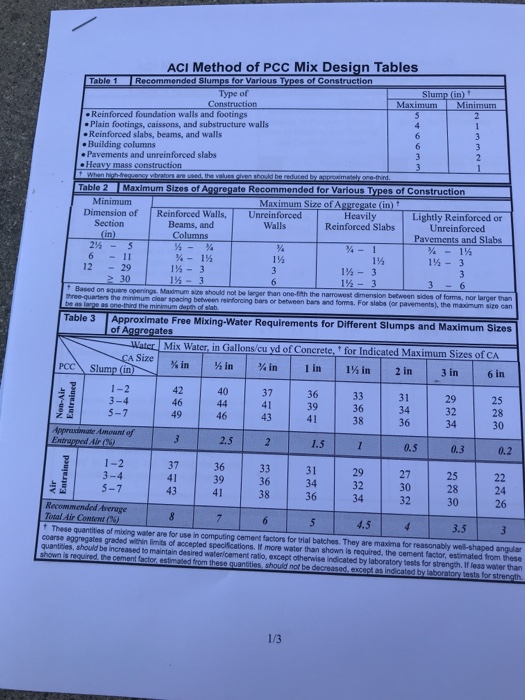

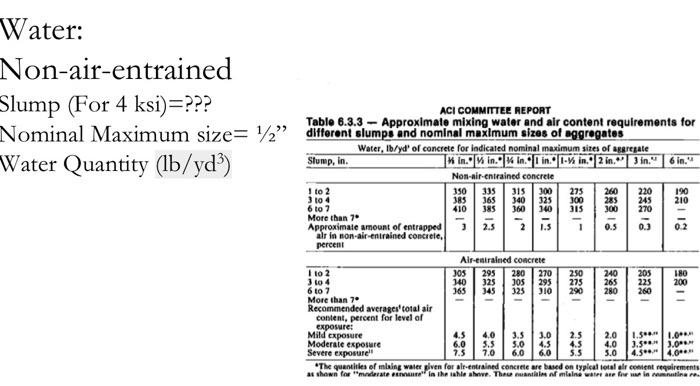

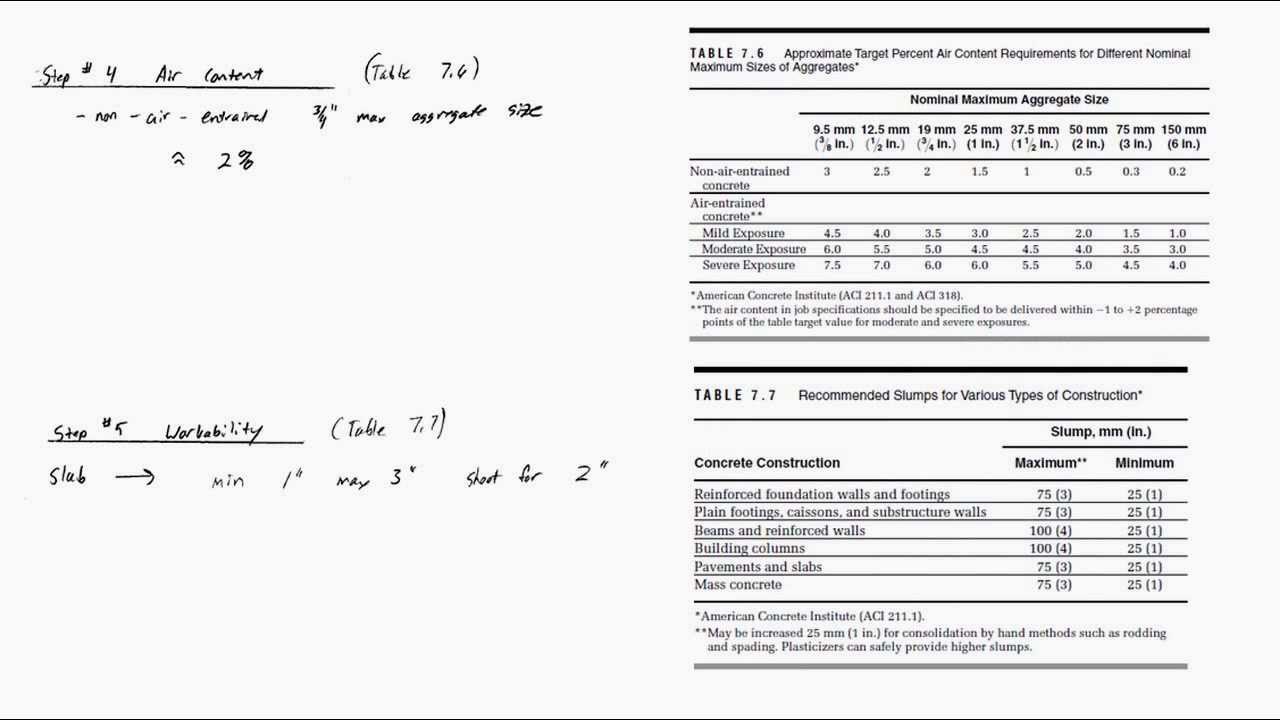

Estimation of mixing water and air content.

Read another article:

4Choice of slump 5Water content selection. This paper describes a procedure specifically developed to achieve self-compacting concrete. Of the limitations of SCC is that there is no established mix design procedure yet. Different concrete mix designs with different materials even with the same proportions can have significantly different properties of strength and. No reinforcing steel will be used so the thumbrule pertaining to clear space between reinforcing bars is not applicable.

Source: goood-design.blogspot.com

Source: goood-design.blogspot.com

This video presents a concrete mixture design example by ACI 211. The standard ACI mix design procedure can be divided into 9 basic steps. The standard ACI mix design procedure can be divided up into 8 basic steps. Mix design means the selection of suitable ingredients of concrete and their relative quantities to obtain an economical concrete with values of certain properties not less than their desired minimum values such as. Aci Tables For Concrete Mix Design.

Source: slideserve.com

Source: slideserve.com

It has the advantages of simplicity in that it. American Concrete Institute Method of Mix Design ACI2111 This method of proportioning was first published in 1944 by ACI committee 613. This video presents a concrete mixture design example by ACI 211. The standard ACI mix design procedure can be divided into 9 basic steps. Ppt Mix Design Powerpoint Presentation Free Download Id 9144278.

The standard ACI mix design procedure can be divided up into 8 basic steps. Calculation of Sand Coarse Aggregate Quantities. Maximum aggregate size selection. Concrete Mix Design procedure using American Standard ACI-211 - YouTube. Aci Tables For Concrete Mix Design.

It has the advantages of simplicity in that it. This video presents a concrete mixture design example by ACI 211. Procedure for ACI Method of Concrete Mix Design. No reinforcing steel will be used so the thumbrule pertaining to clear space between reinforcing bars is not applicable. Aci Tables For Concrete Mix Design.

Source: pinterest.com

Source: pinterest.com

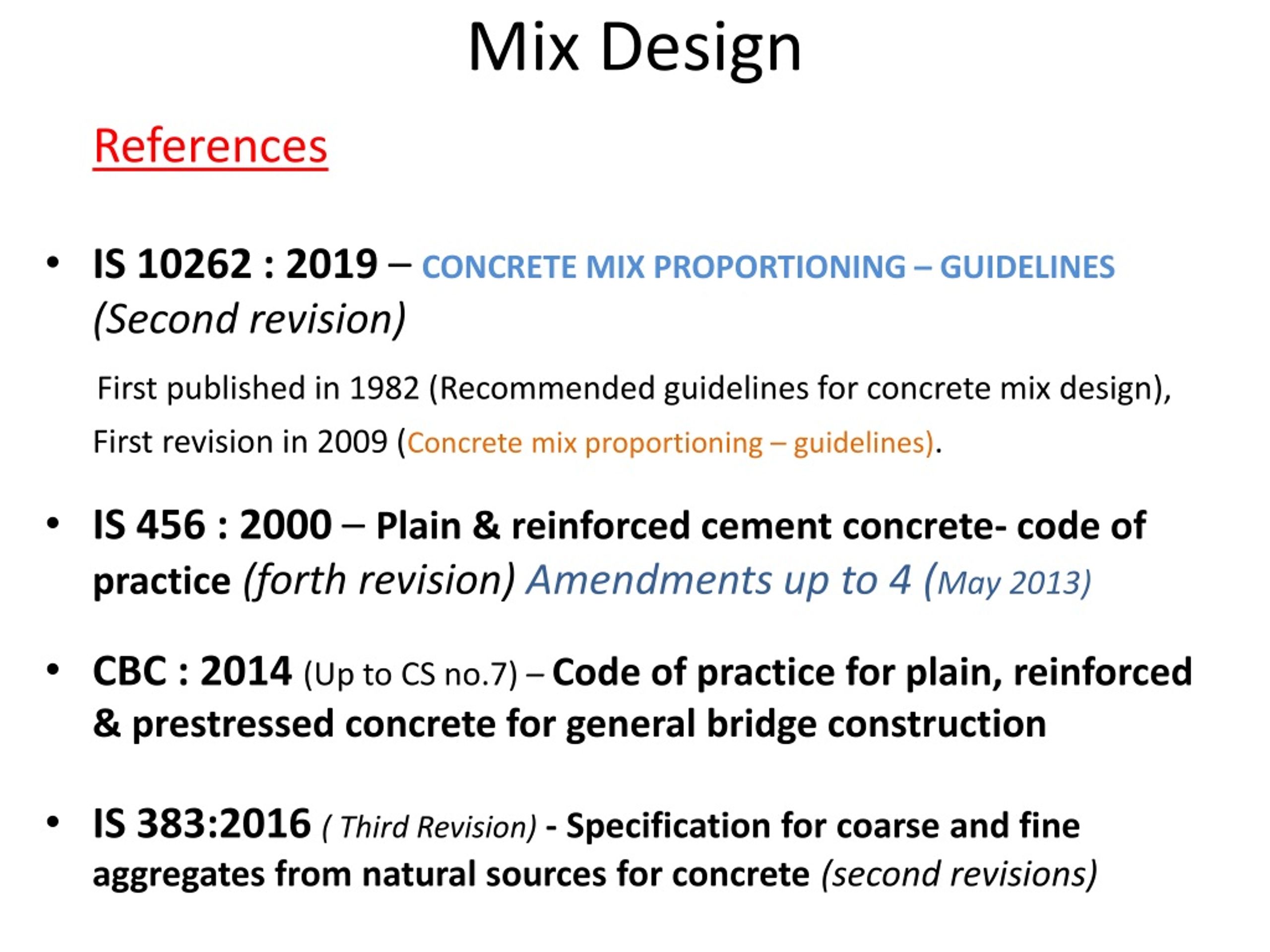

Choice of maximum size of aggregate. Selection of water-cement or water-cementitious material ratio. The absolute volume method of mix design as described by ACI committee 211 is presented. In 1970 the method of ACI mix design became the responsibility of ACI committee 211. Proportions Of Concrete Ingredients By Is Bs And Aci Methods Concrete Mix Design Method Concrete.

Source: goood-design.blogspot.com

Source: goood-design.blogspot.com

ACI Method Of Concrete Mix Design. ACI Mix Design The most common method used in North America is that established by ACI Recommended Practice 2111 Any mix design procedure will provide a first approximation of the proportions and must be checked by trial batches. Mixing Water and Air Content Estimation. Mix design means the selection of suitable ingredients of concrete and their relative quantities to obtain an economical concrete with values of certain properties not less than their desired minimum values such as. Aci Tables For Concrete Mix Design.

Source: goood-design.blogspot.com

Source: goood-design.blogspot.com

If mix designs are submitted for work specified by multiple design professionals eg civil work each design professional specifying concrete mixes should make it clear which mix designs they have reviewed. This paper describes a procedure specifically developed to achieve self-compacting concrete. The standard ACI mix design procedure can be divided into 9 basic steps. This video presents a concrete mixture design example by ACI 211. Aci Tables For Concrete Mix Design.

Source: pinterest.com

Source: pinterest.com

ACI Mix Design The most common method used in North America is that established by ACI Recommended Practice 2111 Any mix design procedure will provide a first approximation of the proportions and must be checked by trial batches. In 1970 the method of mix design became the responsibility of ACI committee 211. Steps of Concrete Mix Design Step-1. The Portland Cement Associations PCA Design and Control of Concrete Mixtures 14th edition 2002 or any earlier edition. Civil Engineering Software List Louiesportsmouth Com Civil Engineering Software Civil Engineering Nursing Student Tips.

Source: semanticscholar.org

Source: semanticscholar.org

Concrete mix design by the ACI method requires various material properties as the input. Specifications and in ACI 318. Steps of Concrete Mix Design Step-1. ACI Method Of Concrete Mix Design. Rational Mix Design Approach For High Strength Concrete Using Sand With Very High Fineness Modulus Semantic Scholar.

Source: civilexperiences.com

Source: civilexperiences.com

The water for required wc ratio to give a 28-day strength of 4000 requirement is 325 lbyd3. 1 inch Class ACI Mix Design Example Class ACI Mix Design Example Step 4. Concrete mix design is the process of selecting suitable ingredients of concrete and determine the relative proportions to produce concrete with certain performance and durability requirements. Estimation of mixing water and air content Step 4. Doe Method Of Concrete Mix Design Concrete Mix Design By Doe Method Civil Experience Best Civil Engineering Blog.

Source: docplayer.net

Source: docplayer.net

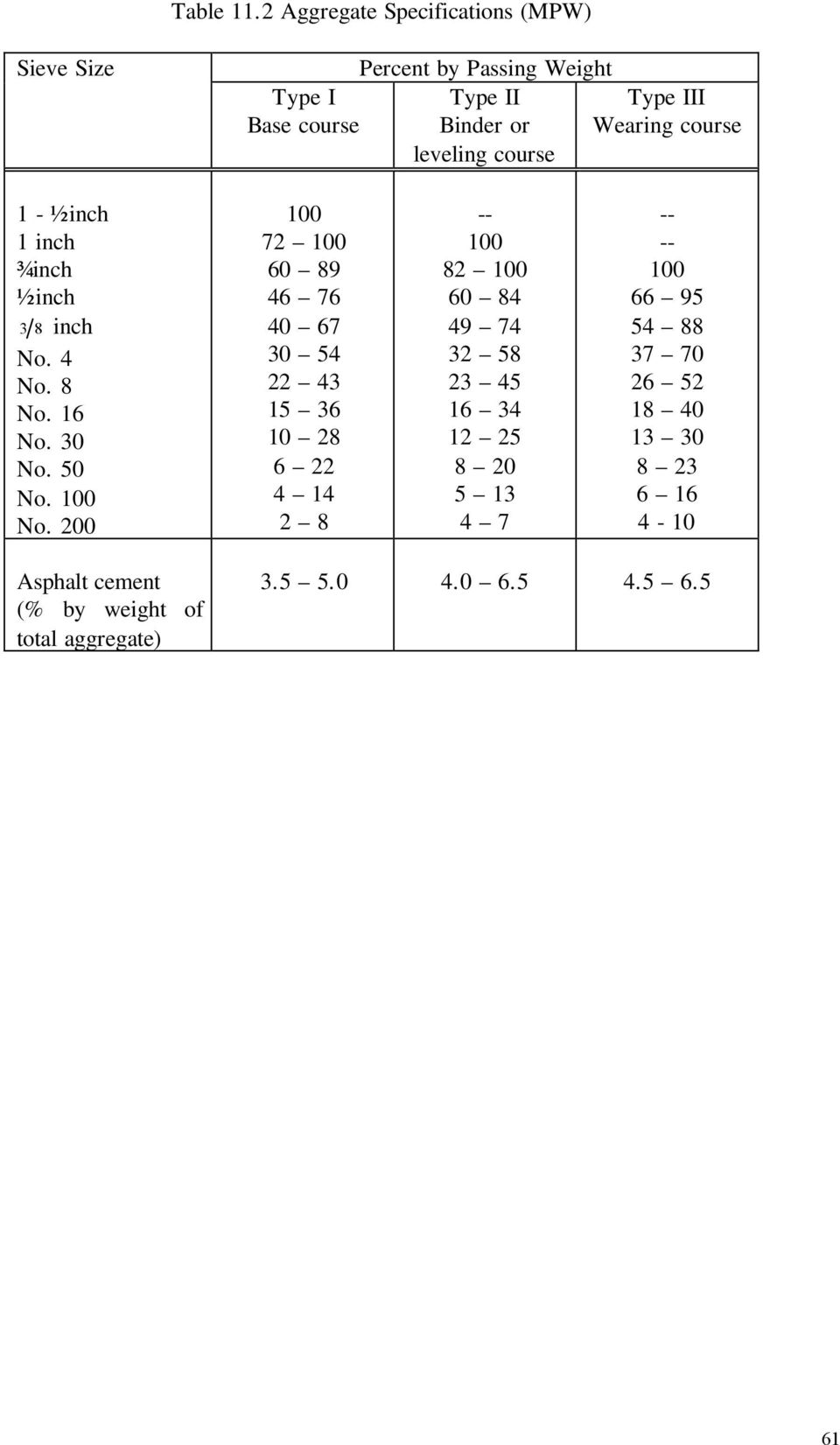

Concrete mix design by the ACI method requires various material properties as the input. In 1970 the method of mix design became the responsibility of ACI committee 211. Aci Method Of Concrete Mix Design. The Portland Cement Associations PCA Design and Control of Concrete Mixtures 14th edition 2002 or any earlier edition. Chapter 11 Marshall Method Of Asphalt Concrete Mix Design Pdf Free Download.

Source: ro.pinterest.com

Source: ro.pinterest.com

From Table3 the estimate Table 2 the recommended air content is 15. If mix designs are submitted for work specified by multiple design professionals eg civil work each design professional specifying concrete mixes should make it clear which mix designs they have reviewed. Estimation of coarse aggregate content. This is well within the general ACI recommendation that the nominal maximum size be limited to 13 of slab depth. Q A 167 What Is C16 20 Denotes Types Of Concrete Concrete Cover Concrete.

Source: goood-design.blogspot.com

Source: goood-design.blogspot.com

The standard ACI mix design procedure can be divided into 9 basic steps. This paper describes a procedure specifically developed to achieve self-compacting concrete. From Table3 the estimate Table 2 the recommended air content is 15. Different concrete mix designs with different materials even with the same proportions can have significantly different properties of strength and. Aci Tables For Concrete Mix Design.

Source: goood-design.blogspot.com

Source: goood-design.blogspot.com

In 1954 the method was revised to include among other modifications the use of entrained air. Mix design means the selection of suitable ingredients of concrete and their relative quantities to obtain an economical concrete with values of certain properties not less than their desired minimum values such as. Concrete mix design by the ACI method requires various material properties as the input. The standard ACI mix design procedure can be divided into 9 basic steps. Aci Tables For Concrete Mix Design.

In addition the test results for acceptance characteristics for self-compacting concrete such as slump flow J-ring V-funnel and L-Box are presented. American Concrete Institute Method of Mix Design ACI2111 This method of proportioning was first published in 1944 by ACI committee 613. In 1954 the method was revised to include among other modifications the use of entrained air. 9Adjustments for aggregate moisture 1The required target average compressive strength. Sustainable Concrete Mix Design.