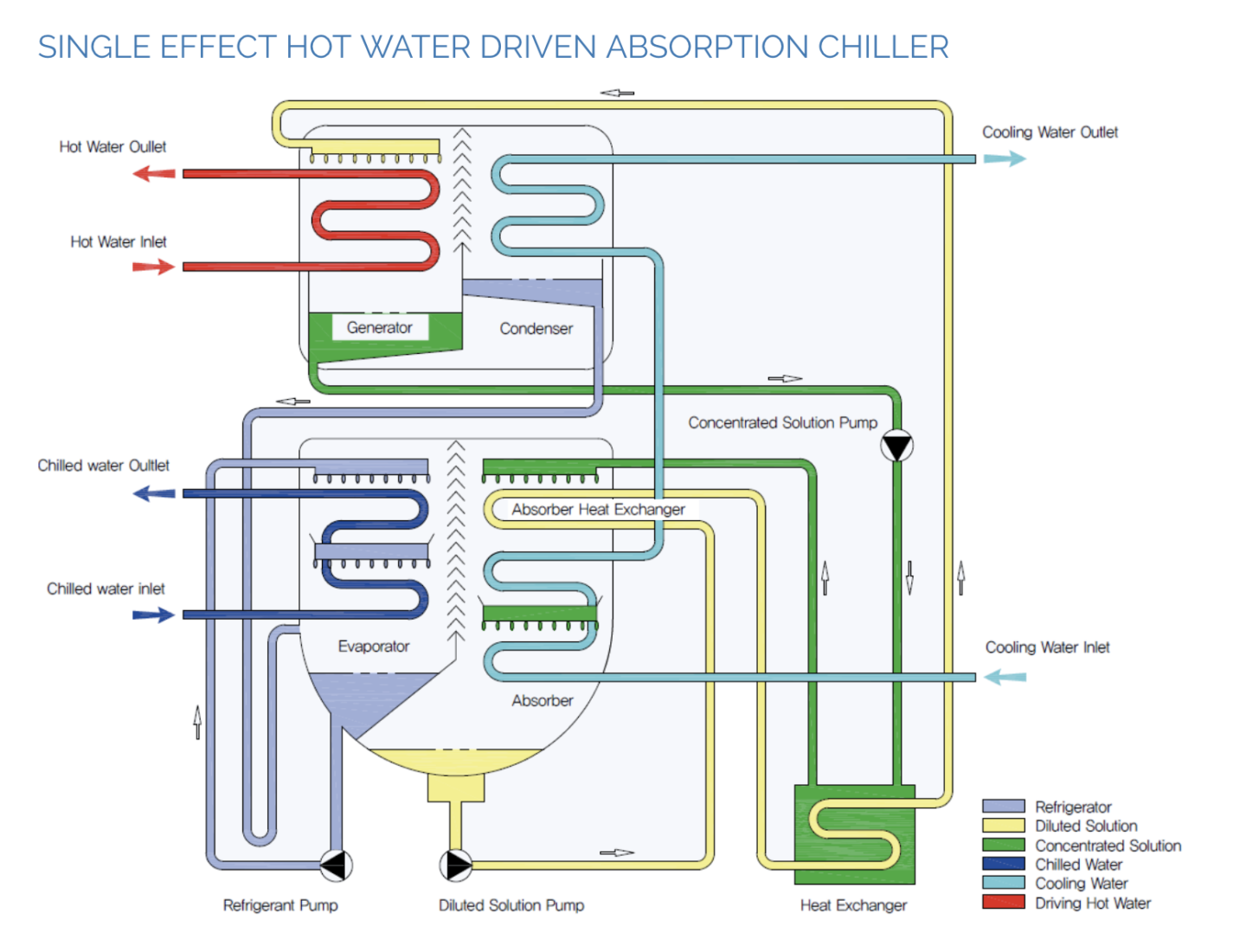

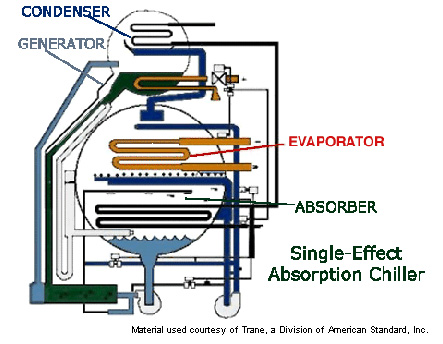

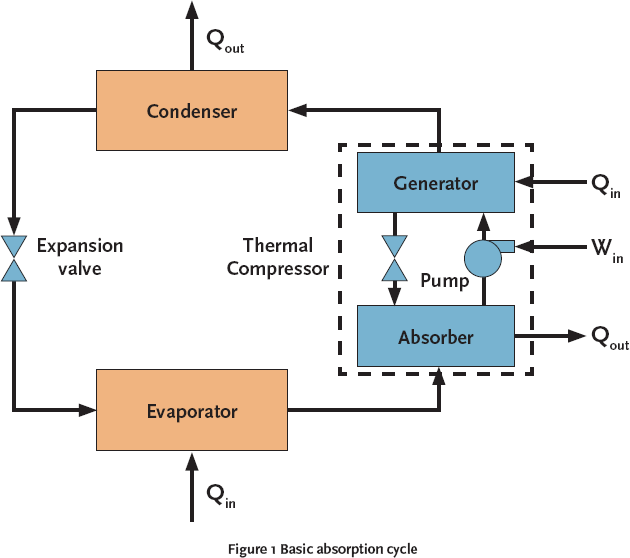

Instead they use water as the refrigerant and this is mixed with either ammonia or Lithium Bromide. Built to last Absorption chillers are built to last under the most extreme conditions for many decades Zudek design them to last for more than 30 years. Ammonia absorption chiller design.

Ammonia Absorption Chiller Design, Absorption Chiller How it works. Built to last Absorption chillers are built to last under the most extreme conditions for many decades Zudek design them to last for more than 30 years. Instead they use water as the refrigerant and this is mixed with either ammonia or Lithium Bromide. The chiller has a nominal refrigeration capacity of 12 kW at conditions of ambient air temperature of 35C and chilled water flow temperature of 5C.

Modeling Of Ammonia Absorption Chillers Integration In Energy Systems Of Process Plants Sciencedirect From sciencedirect.com

Modeling Of Ammonia Absorption Chillers Integration In Energy Systems Of Process Plants Sciencedirect From sciencedirect.com

The ammonia-water solution quantity lower hydraulic pressure drops and a compact final design. The chiller has a nominal refrigeration capacity of 12 kW at conditions of ambient air temperature of 35C and chilled water flow temperature of 5C. It is not common knowledge that refrigeration down up to -60C from thermal energy is a possible solution. Thanks at 20 years of experience in Ammonia Absorption Refrigeration Plants we designed and implemented Ammonia Absorption Chillers Skid Units that could be operated with low grade waste heat from 80 C.

An interesting point to note about absorption chillers is that they dont use conventional refrigerants.

Read another article:

This installation consists of two 415 kW reciprocating engine generators and an absorption chiller that produces 160 tons of 25F refrigeration from the engine waste heat. Available absorption chillers mainly use two types of working fluids. Carbon dioxide fire extinguisher. They use heat sources such as hot water exhaust gas gas and oil firing and Steam. Design fabrication and installation of ammonia absorption chillers.

Source: goenergylink.com

Source: goenergylink.com

The system uses two coolants the first of which performs evaporative cooling and is then absorbed into the second coolant. Goldman Energy can supply a wide range of Absorption Chillers and Heat Pumps from World Energy that can be adapted to your specific needs. Dynamic Model for Small-Capacity Ammonia-Water Absorption Chiller Vinodh K. Built to last Absorption chillers are built to last under the most extreme conditions for many decades Zudek design them to last for more than 30 years. How Absorption Chillers Work Energylink.

Source: pinterest.com

Source: pinterest.com

The latter needs a rectifier to remove the vapor water produced in the. Systems are rated at up to 120000 BTUhour. DIY Solar Absorption Cooler. The composite adsorption chiller based on ammonia was developed in the literature 8085. Vapor Absorption System Circuit Diagram Refrigeration And Air Conditioning Circuit.

Source: c03.apogee.net

Source: c03.apogee.net

The literature values for the design of the Aqua Ammonia vapour absorption system are. Case Study of Ammonia Chillers. We recently attended an ammonia chiller factory on mainland Europe. Looking at the design calculations for ammonia as opposed to other refrigerants- it is by far the best refrigerant for industrial applications. Commercial Library.

Source: cibsejournal.com

Source: cibsejournal.com

Woodruff School of Mechanical Engineering Georgia Institute of Technology Atlanta GA 30032 404 894-7479. Serves the oil gas petrochemical and refining industries. Stainless steel charging valve. It is not common knowledge that refrigeration down up to -60C from thermal energy is a possible solution. Module 10 Absorption Refrigeration Cibse Journal.

Source: researchgate.net

Source: researchgate.net

Low maintenance Being an oil free system with only one pump maintenance is reduced helping companies to. Woodruff School of Mechanical Engineering Georgia Institute of Technology Atlanta GA 30032 404 894-7479. They use heat sources such as hot water exhaust gas gas and oil firing and Steam. Case Study of Ammonia Chillers. Working Principle Of An Absorption Chiller Download Scientific Diagram.

Source: esmagazine.com

Source: esmagazine.com

Built to last Absorption chillers are built to last under the most extreme conditions for many decades Zudek design them to last for more than 30 years. Design Conditions for the 3TR Aqua Ammonia Refrigeration System. DIY Solar Absorption Cooler. Systems are rated at up to 120000 BTUhour. Basics For Absorption Chillers 2009 03 01 Engineered Systems Magazine.

Source: vamtec.com

Source: vamtec.com

Systems are rated at up to 120000 BTUhour. Capacity of system 3TR10548KW Concentration of NH 3 in refrigerant X r 098 Concentration of NH 3 in Solution X s 042 Concentration of NH 3 in absorbent X w 038 Temperature of the evaporator T. The IPLV efficiency is 12 percent higher in an ammonia chiller. Originally Posted by McFranklin So let me get this straight you have a junk compressor a junk diesel motor and you want to cobble it together so that in the MIDDLE OF SUMMER you add HEAT to your swimming pool. Vamtec Yazaki Hot Water Absorption Chiller 17kw To 352kw Cooling From Waste Heat.

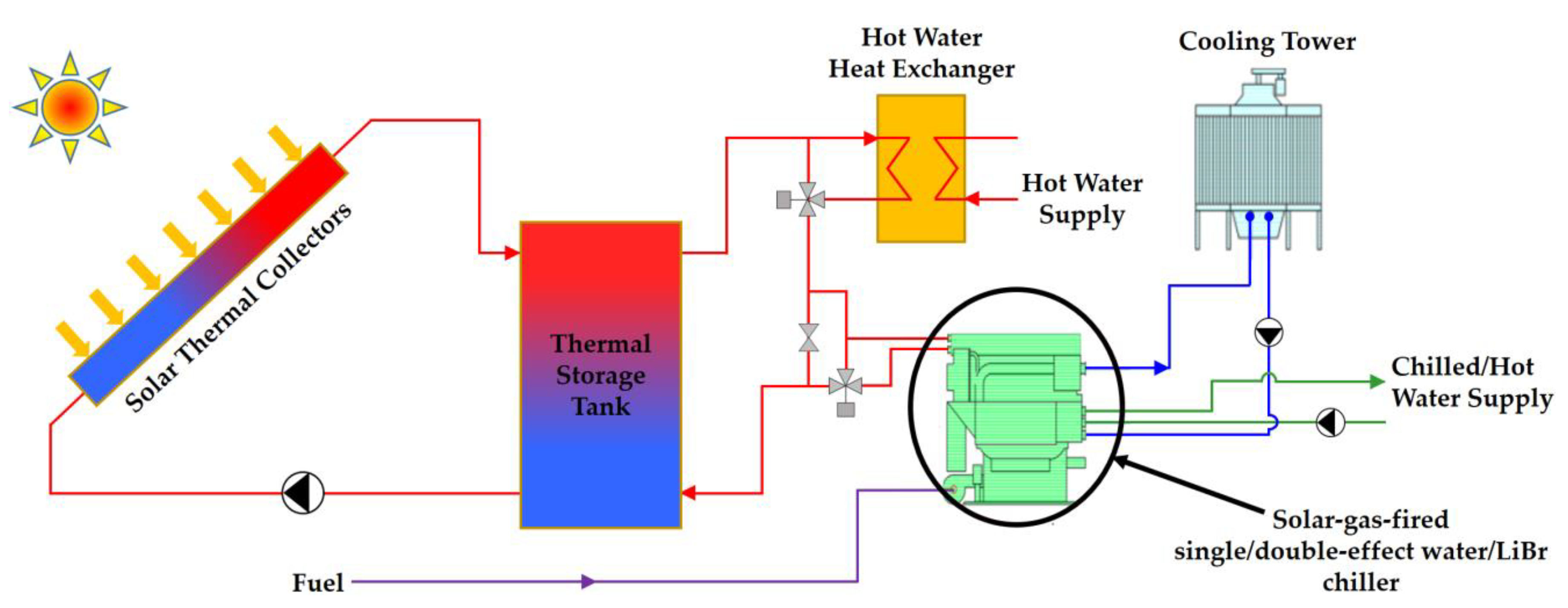

At a cost of electricity of about 7 centskWh the ammonia chiller will be cost competitive over its lifetime. An interesting point to note about absorption chillers is that they dont use conventional refrigerants. Capacity of system 3TR10548KW Concentration of NH 3 in refrigerant X r 098 Concentration of NH 3 in Solution X s 042 Concentration of NH 3 in absorbent X w 038 Temperature of the evaporator T. Case Study of Ammonia Chillers. Schematic Of A Single Effect Solar Absorption Chiller Adapted From 2 Download Scientific Diagram.

Source: achrnews.com

Source: achrnews.com

In this article we learn how to design a simple PWM speed controller for a. While the products were first produced commercially in 1923 it was only in the 60s that serious production started due to rising demand for caravan. Absorption Chiller How it works. Refrigerant types and their future. Using Low Grade Waste Steam To Power Absorption Chillers 2015 05 04 Achrnews Achr News.

Source: sciencedirect.com

Source: sciencedirect.com

The system uses two coolants the first of which performs evaporative cooling and is then absorbed into the second coolant. An equation-oriented model for the design of a simple ammoniawater absorption refrigeration cycle is presented which due to the nature of the working mixture includes high-quality thermodynamic. Absorption Chiller How it works. Stainless steel charging valve. Modeling Of Ammonia Absorption Chillers Integration In Energy Systems Of Process Plants Sciencedirect.

Source: theengineeringmindset.com

Source: theengineeringmindset.com

An interesting point to note about absorption chillers is that they dont use conventional refrigerants. Available absorption chillers mainly use two types of working fluids. First cost of the ammonia chiller is twice that of an R-134a chiller. Design Conditions for the 3TR Aqua Ammonia Refrigeration System. Absorption Chiller How It Works The Engineering Mindset.

Source: researchgate.net

Source: researchgate.net

Looking at the design calculations for ammonia as opposed to other refrigerants- it is by far the best refrigerant for industrial applications. While the products were first produced commercially in 1923 it was only in the 60s that serious production started due to rising demand for caravan. Looking at the design calculations for ammonia as opposed to other refrigerants- it is by far the best refrigerant for industrial applications. An interesting point to note about absorption chillers is that they dont use conventional refrigerants. Schematic Of Tes Comprising Sofc And Absorption Chiller 45 The Download Scientific Diagram.

Source: mdpi.com

Source: mdpi.com

The ammonia chiller has a much better part-load efficiency. Paul Evans-Sep 26 2017 7. The CaCl 2 activated carbon and CaCl 2 expanded natural graphite with ammonia as working pairs and heat pipe were presented in the literature 83 84. Originally Posted by McFranklin So let me get this straight you have a junk compressor a junk diesel motor and you want to cobble it together so that in the MIDDLE OF SUMMER you add HEAT to your swimming pool. Applied Sciences Free Full Text New Developments And Progress In Absorption Chillers For Solar Cooling Applications Html.

Source: sciencedirect.com

Source: sciencedirect.com

Design fabrication and installation of ammonia absorption chillers. Available absorption chillers mainly use two types of working fluids. WaterLiBr water as refrigerant and LiBr as absorbent and ammoniawater ammonia as refrigerant and water as absorbent. The IPLV efficiency is 12 percent higher in an ammonia chiller. Effect Absorption Chiller An Overview Sciencedirect Topics.

Source: esmagazine.com

Source: esmagazine.com

The IPLV efficiency is 12 percent higher in an ammonia chiller. We were shown through the process of production and were shown videos of a retrofit. The 5 kW cooling capacity ammonia-water absorption chiller described in this paper was especially designed for solar cooling applications in this way. Determan and Srinivas Garimella Sustainable Thermal Systems Laboratory George W. Basics For Absorption Chillers 2009 03 01 Engineered Systems Magazine.