Process by which a new product idea is conceived investigated taken through the design process manufactured marketed and serviced. The DSM has been actively used at Ford for nearly 10 years and several of the CSIs had learned about it while obtaining advanced engineering degrees at MIT. Automotive design process pdf.

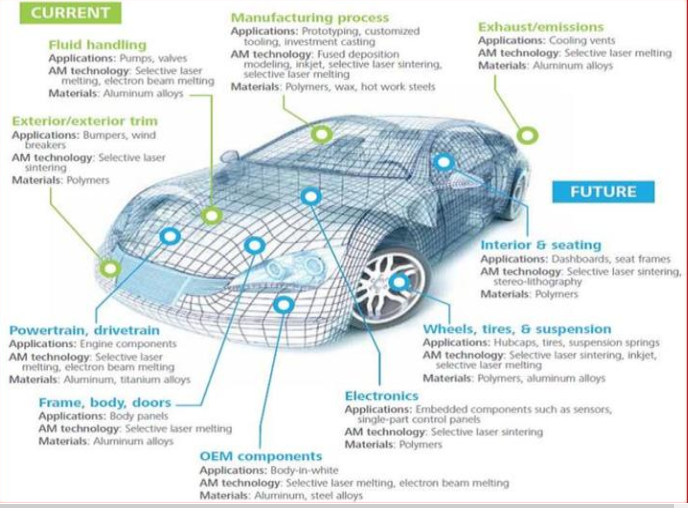

Automotive Design Process Pdf, 521 The Option Value of the Number of Design Alternatives 166 522 The Optimal Development Process Setup. Manufacturing processes used to produce finished gear specifications have certain capability limitations. Reducing the weight of body frame and engine components should translate to fuel economy. Design Plans Manufacturing Plans Process Control Plans.

Linear Cost Structure 168 523 The Optimal Development Process Setup. Automotive design is the process of developing the appearance and to some extent the ergonomics of motor vehicles including automobiles motorcycles trucks buses coaches and vans. Electric Machine Parameter and Testing Part 2. Measure and record A-B B-C C-A line-line resistances and inductances.

Fail-safe design Automotive Embedded Systems 14 ABS Anti-lock Breaking System.

Read another article:

The automotive industry is one of the worlds most innovative industries. Automotive design is the process of developing the appearance and to some extent the ergonomics of motor vehicles including automobiles motorcycles trucks buses coaches and vans. Process assessment is a disciplined evaluation of an organizational units processes against a process assessment model. The automotive industry is one of the worlds most innovative industries. In the automotive industry within the context of ISOTS169492002 the automotive quality management system international standard these related to the product realization.

Source: pinterest.com

Source: pinterest.com

Hipot and surge test the stator after varnish at 1800VAC max current leakage 5mA Before and after varnish perform corona test partial discharge with pulse up. Rubbery processing region so making it less suitable for stretching processes like blow moulding and thermoforming Designers must design for process as well as purpose and material. With a view to ensuring quality reliability and economic efficiency the manufacture of vehicles and automotive components such as engines and gearboxes is only possible in automated manufacturing facilities. Identification of Analysis Tools to Support the Design Methodology The second goal of this research was to identify a set of analysis and design tools to support manufacturing process design. Automotiveembedded Systemshandbook Information Technology Technology Automotive Engineering.

Source: newkidscar.com

Source: newkidscar.com

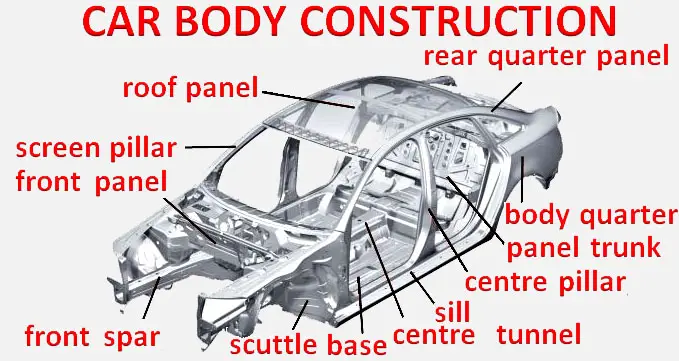

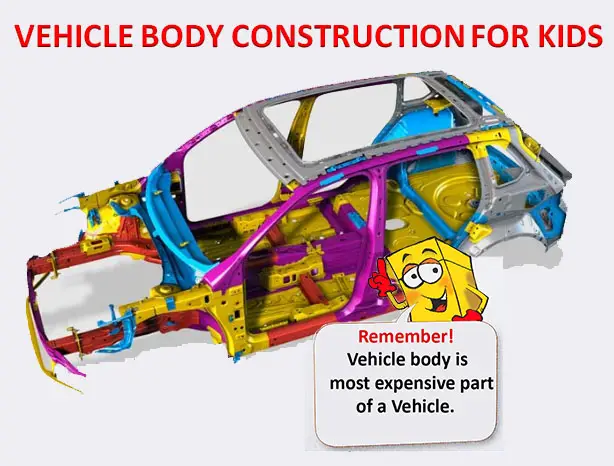

To ensure capable processes this includes considering both process design considerations and established business requirements. Business Process Management for Automotive End of Life Processes 5 Figure 1 illustrates an overview of the design development delivery disposal and recovery cycle of automotive components assemblies and systems. If some fault is detected ABS stops functioning. Materials and Process Selection for Engineering Design. Vehicle Body Construction Car Construction.

Source: pinterest.com

Source: pinterest.com

Reference Data from J1211 Nov 1978 J12132 Glossary of Reliability Terminology Associated With Automotive Electronics. Design process while assuring the reliability of new vehicle designs. In the automotive industry within the context of ISOTS169492002 the automotive quality management system international standard these related to the product realization. Model Based Design approach for Automotive applications 7 MBD approach for Powertrain Systems System analysis and design for optimum performance Control function development Auto-coding Early VV of control function Real Physical System Virtualized Model Integration with Standard function and VV. Catia Exercise Book Pdf Technical Drawing Computer Aided Design Technical Drawing Engineering Design Process Solidworks Tutorial.

Source: newkidscar.com

Source: newkidscar.com

Ideally product development is performed by an interdisciplinary team with representatives from different segments of an industrial enterprise including engineering design materials and manufacturing finance legal sales and marketing. The functional design and development of a modern motor vehicle is typically done by a large team from many different disciplines included within automotive engineering however design roles are not. Process by which a new product idea is conceived investigated taken through the design process manufactured marketed and serviced. Non-Linear Cost Structure 172 53 Five Principles of Automotive Development 173 531 Capabilities in Platform Design and Developing Sets Concurrently 174. Vehicle Body Construction Car Construction.

Process by which a new product idea is conceived investigated taken through the design process manufactured marketed and serviced. Business Process Management for Automotive End of Life Processes 5 Figure 1 illustrates an overview of the design development delivery disposal and recovery cycle of automotive components assemblies and systems. 11 Overview of casting processes and their use in automotive applications Automotive casting processes can be differentiated according to A mould filling and B moulding technologies. DSMs are built by interviewing participants in the process. 2.

Source: pinterest.com

Source: pinterest.com

In Noor the design process for doors was documented using the Design Structure Matrix DSM methodology Eppinger et al. The Automotive SPICE process assessment model PAM is intended for use when performing conformant assessments of the process capability on the development of. Business Process Management for Automotive End of Life Processes 5 Figure 1 illustrates an overview of the design development delivery disposal and recovery cycle of automotive components assemblies and systems. J1938 DesignProcess Checklist for Vehicle Electronic Systems J2837 Environmental Conditions and Design Practices for Automotive Electrical Electronic Equipment. Peugeot Rcz Blueprints Ai Cdr Cdw Dwg Dxf Eps Gif Jpg Pdf Pct Psd Svg Tif Bmp Nissan 370z Peugeot Nissan.

Source: pinterest.com

Source: pinterest.com

In Noor the design process for doors was documented using the Design Structure Matrix DSM methodology Eppinger et al. Rubbery processing region so making it less suitable for stretching processes like blow moulding and thermoforming Designers must design for process as well as purpose and material. In Noor the design process for doors was documented using the Design Structure Matrix DSM methodology Eppinger et al. The drawing or design model shall reflect the changeNIC level and revision level of the parts undergoing the Process Audit. Automobile Engineering By Kirpal Singh Pdf Mechanical Geek Automobile Engineering Automotive Engineering Engineering.

Source: teachengineering.org

Source: teachengineering.org

Mahmoud Farag 28 Chapter 1 Summary 1 1. Measure and record A-B B-C C-A line-line resistances and inductances. Stages of manufacturing processes are to be accordingly decided. In the automotive industry within the context of ISOTS169492002 the automotive quality management system international standard these related to the product realization. Design Step 1 Identify The Need Activity Teachengineering.

Source: pinterest.com

Source: pinterest.com

Reference Data from J1211 Nov 1978 J12132 Glossary of Reliability Terminology Associated With Automotive Electronics. Electric Machine Parameter and Testing Part 2. Ideally product development is performed by an interdisciplinary team with representatives from different segments of an industrial enterprise including engineering design materials and manufacturing finance legal sales and marketing. Expected outcomeconcept In order to advice a solution we need to consider the latest technology innovation techniques and material and increase the comfort and convenience in automotive car dash board with decreasing the amount of vibration and noise in the cabin. 2020 Audi A3 Sportback Audi Car Interior Design Design.

Source: pinterest.com

Source: pinterest.com

The drawing or design model shall reflect the changeNIC level and revision level of the parts undergoing the Process Audit. The software design process involves gaining knowledge about a problem and about its technical solution. To ensure capable processes this includes considering both process design considerations and established business requirements. Stamping processes to be used for a panel depend on its design. Lambo Illustration Process By P Ruperto Car Design Sketch Car Design Car Drawings.

Source: pinterest.com

Source: pinterest.com

Design process while assuring the reliability of new vehicle designs. 1 Green sand casting. The functional design and development of a modern motor vehicle is typically done by a large team from many different disciplines included within automotive engineering however design roles are not. If some fault is detected ABS stops functioning. Pdf Download Industrial Design An Indispensable Guide All The Details Industrial Designers N Design Reference Industrial Design Portfolio Industrial Design.

Source: pinterest.com

Source: pinterest.com

Stamping processes to be used for a panel depend on its design. J1938 DesignProcess Checklist for Vehicle Electronic Systems J2837 Environmental Conditions and Design Practices for Automotive Electrical Electronic Equipment. Measure and record A-B B-C C-A line-line resistances and inductances. Design responsible Suppliers are shall consider Design for Serviceability which ensures ease of disassembly of product with minimal cost and time. H Point The Fundamentals Of Car Design Packaging Car Design Packaging Design Automotive Design.

Source: pinterest.com

Source: pinterest.com

Ideally product development is performed by an interdisciplinary team with representatives from different segments of an industrial enterprise including engineering design materials and manufacturing finance legal sales and marketing. Then the brake works though a skid cannot be avoided. Linear Cost Structure 168 523 The Optimal Development Process Setup. 11 Overview of casting processes and their use in automotive applications Automotive casting processes can be differentiated according to A mould filling and B moulding technologies. Nx General Packaging 4086 Tcm1023 4583 Pdf Automotive Design Packaging Design.

Source: sciencedirect.com

Source: sciencedirect.com

Reducing the weight of body frame and engine components should translate to fuel economy. If some fault is detected ABS stops functioning. The automotive industry is one of the worlds most innovative industries. Figure 1 Design development delivery disposal and recovery cycle of automotive components assemblies and systems. End Of Life Vehicle An Overview Sciencedirect Topics.

Source: article.sapub.org

Source: article.sapub.org

The functional design and development of a modern motor vehicle is typically done by a large team from many different disciplines included within automotive engineering however design roles are not. Introduction to Production Part Approval Process PPAP Production Part Approval Process PPAP defines generic requirements for production part approval. Ideally product development is performed by an interdisciplinary team with representatives from different segments of an industrial enterprise including engineering design materials and manufacturing finance legal sales and marketing. Design Plans Manufacturing Plans Process Control Plans. Materials Used In Automotive Manufacture And Material Selection Using Ashby Charts.