For an axial design where the head is achieved by reaction only. 1 Axial thrust Axial forces acting on the rotor in the case of a single-stage centrifugal pumpThe axial impeller force F1 is the difference between the axial forces on the discharge-side Fd and suction-side Fs impeller shroud F1 Fd FsMomentum FJ is a force which constantly acts. Axial pump design.

Axial Pump Design, The manner in which fluid flows through the pump is determined by the design of the pump casing and the impeller. As a general rule axial flow pumps are usually selected for pumping large volumes of water against relatively low heads 115 m. Determination of Impeller Hub-Ratio and Blade Number. Sulzer offers a complete range of low and high pressure horizontal and vertical axial flow pumps especially designed to handle severe pumping conditions.

Components Of Centrifugal Pump Centrifugal Pump Pumps Diy Water Pump From pinterest.com

Components Of Centrifugal Pump Centrifugal Pump Pumps Diy Water Pump From pinterest.com

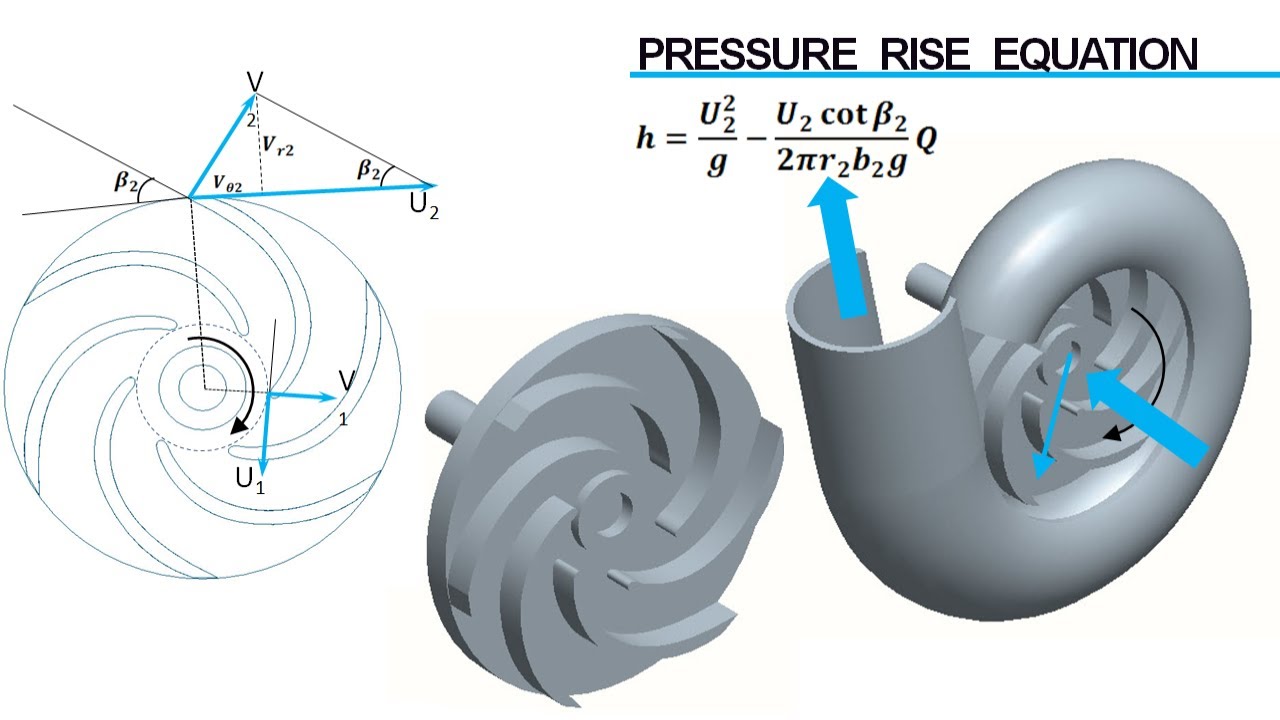

The pressure in the casing is developed by the flow of liquid over the blades of the impeller. Centrifugal pumps can be classified based on the manner in which fluid flows through the pump. A mixed flow pump with an adjustable geometry nozzle is probably an easier more reliable way to get the same performance flexibility. One criterion for the design is the specific.

When the axial-flow pump is working under off-design condition the attack angle which causes hydraulic loss will always exist at the leading edge of the guide vane.

Read another article:

In this design calculated value of specific speed based on required head and capacity is 877 rpm and it is within the range of high specific speed pump that is 400 and 1200. In this design calculated value of specific speed based on required head and capacity is 877 rpm and it is within the range of high specific speed pump that is 400 and 1200. An axial flow pump with variable pitch is one choice. For large-diameter propellers normally manufactured for operation in air the maximum design velocity should be less than about 10 msec because the propeller hib is designed for stresses related to high-speed low-resistance operation. An axial piston pump has a number of pistons usually an odd number arranged in a circular array within a housing which is commonly referred to as a cylinder block rotor or barrelThis cylinder block is driven to rotate about its axis of symmetry by an integral shaft that is more or less aligned with the pumping pistons usually parallel but not necessarily.

Source: pinterest.com

Source: pinterest.com

P Flados Jan 21 2013. A design of axial pump is carried out and analyzed to get the best performance point. Sulzer offers a complete range of low and high pressure horizontal and vertical axial flow pumps especially designed to handle severe pumping conditions. In general the swash plate design is used for pumps and the bent axis design for motors although there are applications where this is not the best solution. 12 Swash Plate Piston Pump الجزء الاول Youtube Hydraulic Systems Swash Pistons.

Source: pinterest.com

Source: pinterest.com

Sulzer offers a complete range of low and high pressure horizontal and vertical axial flow pumps especially designed to handle severe pumping conditions. In general the swash plate design is used for pumps and the bent axis design for motors although there are applications where this is not the best solution. The three types of flow through a centrifugal pump are radial flow axial flow and mixed flow. Axial Flow Propeller Pumps - Design Construction Features. Centrifugal Pump Working Centrifugal Pump Mechanical Engineering Technology Mechanical Engineering Design.

Source: pinterest.com

Source: pinterest.com

An axial flow pump with variable pitch is one choice. This family of pumps is specifically designed for low-head movement of water for a multitude of municipal agricultural and industrial services. The design and performance analysis of axial pump are chosen because it is the most useful mechanical rotodynamic machine in fluid works which widely used in domestic irrigation industry large plants and river water pumping system. So axial flow pump type that is high specific speed pump is chosen in this study. Axial Split Case Centrifugal Pump China Axially Split Pump Manufacturer Centrifugal Pump Vacuum Pump Axial.

Source: pinterest.com

Source: pinterest.com

A mixed flow pump with an adjustable geometry nozzle is probably an easier more reliable way to get the same performance flexibility. However a good efficiency and a technically reasonable pump size for high volume capacities and low heads can only be achieved with axial pumps. Determination of Impeller Hub-Ratio and Blade Number. The three types of flow through a centrifugal pump are radial flow axial flow and mixed flow. Centrifugal Pumps Principles Properties And Applications Centrifugal Pump Diy Water Pump Refrigeration And Air Conditioning.

Source: pinterest.com

Source: pinterest.com

They are generally the pump of choice for flows over 5Lmin and up to 415 bar if budgets allow. It has an impeller inside the pipe. One criterion for the design is the specific. There can be extensive overlap in. Pin On Pumps.

Source: ar.pinterest.com

Source: ar.pinterest.com

An axial flow pump with variable pitch is one choice. The manner in which fluid flows through the pump is determined by the design of the pump casing and the impeller. As a general rule axial flow pumps are usually selected for pumping large volumes of water against relatively low heads 115 m. They are generally the pump of choice for flows over 5Lmin and up to 415 bar if budgets allow. Acvp Axial Concrete Volute Pump Rotor.

Source: pinterest.com

Source: pinterest.com

This lead was followed by other factories that endeavoured to become leading manufacturers of centrifugal pump design and after this the design of helicoidal diagonal and axial flow pumps was developed rapidly. It has an impeller inside the pipe. The three types of flow through a centrifugal pump are radial flow axial flow and mixed flow. Sizing design of Axial Flow Pump. P40vr 11 Cc 10j Tokyo Keiki Tokimec Swash Plate Type Variable Piston Pump P V Serie Pistons Swash Pumps.

Source: pinterest.com

Source: pinterest.com

For boating also consider the mechanical side of the issue. Axial Flow Propeller Pumps - Design Construction Features. Vertical Axial Flow Pumps The AFV axial flow suspended shaft vertical pump is a single-stage propeller type machine. This is because the traditional guide vane is fixed on the guide vane hub with a fixed angle for the design condition and cannot be adjustable with the change in working conditions. Introduction To Centrifugal Pumps The Piping Engineering World In 2021 Centrifugal Pump Engineering Pumps.

Source: pinterest.com

Source: pinterest.com

An axial flow pump with variable pitch is one choice. A mixed flow pump with an adjustable geometry nozzle is probably an easier more reliable way to get the same performance flexibility. Axial Flow Propeller Pumps - Design Construction Features. When the axial-flow pump is working under off-design condition the attack angle which causes hydraulic loss will always exist at the leading edge of the guide vane. Hydraulic Piston Diagram Google Search Automotive Engineering Mechanical Engineering Hydraulic Systems.

Source: pinterest.com

Source: pinterest.com

A design of axial pump is carried out and analyzed to get the best performance point. In principle this requirement could also be met by using radial or mixed-flow impellers. For use as a design factor Equation I can be used to solve for the design velocity assuming a pump diameter. Sizing design of Axial Flow Pump. Warman Q Series Qcl Axial Flow Pump Warman Axial Fittings.

Source: in.pinterest.com

Source: in.pinterest.com

The design and performance analysis of axial pump are chosen because it is the most useful mechanical rotodynamic machine in fluid works which widely used in domestic irrigation industry large plants and river water pumping system. Axial flow pumps also known as elbow or propeller pumps are used in high flow and low head applications. Vertical Axial Flow Pumps The AFV axial flow suspended shaft vertical pump is a single-stage propeller type machine. Axial Pump Profiler and Blade Design Software. Zlb Vertical Axial Flow Pump Features The Transmission Temperature Should Not Be Above 50 This Axial Submersible Pump Industrial Pumps Sand And Gravel.

Source: pinterest.com

Source: pinterest.com

Sulzer offers a complete range of low and high pressure horizontal and vertical axial flow pumps especially designed to handle severe pumping conditions. An axial piston pump has a number of pistons usually an odd number arranged in a circular array within a housing which is commonly referred to as a cylinder block rotor or barrelThis cylinder block is driven to rotate about its axis of symmetry by an integral shaft that is more or less aligned with the pumping pistons usually parallel but not necessarily. This lead was followed by other factories that endeavoured to become leading manufacturers of centrifugal pump design and after this the design of helicoidal diagonal and axial flow pumps was developed rapidly. Their simple but heavy construction multiple hydraulic combinations and available. Axial Steam Engines Steam Engine Steam Engineering.

Source: pinterest.com

Source: pinterest.com

Sizing design of Axial Flow Pump. Their simple but heavy construction multiple hydraulic combinations and available. Axial Pump Profiler and Blade Design Software. P Flados Jan 21 2013. Danfoss Axial Pump Introduction Animation Pumps Axial Power Engineering.

Source: pinterest.com

Source: pinterest.com

A wide range of geometric tools and interactive charts allows users to configure the axial pumps blades easily and in a short time of time. Sulzer offers a complete range of low and high pressure horizontal and vertical axial flow pumps especially designed to handle severe pumping conditions. Axial Flow is a common type of pump that essentially consists of an impeller in a pipe operating in a casing. They are generally the pump of choice for flows over 5Lmin and up to 415 bar if budgets allow. Sliding Vane Pump Information Pompe.

Source: pinterest.com

Source: pinterest.com

However a good efficiency and a technically reasonable pump size for high volume capacities and low heads can only be achieved with axial pumps. A mixed flow pump with an adjustable geometry nozzle is probably an easier more reliable way to get the same performance flexibility. The rapid input setup and computer run time for this meanline pump flow code make it an effective analysis and conceptual design tool. Their simple but heavy construction multiple hydraulic combinations and available. Introduction To Centrifugal Pumps The Piping Engineering World In 2021 Centrifugal Pump Engineering Pumps.