The bioreactor is the heart of any biochemical process in which enzymes microbial mam-malian or plant cell systems are used for manufacture of a wide range of useful biological products. The first consideration in the design of this bioreactor was to apply systems-engineering principles to ensure robust and reliable performance. Bioreactor design calculations.

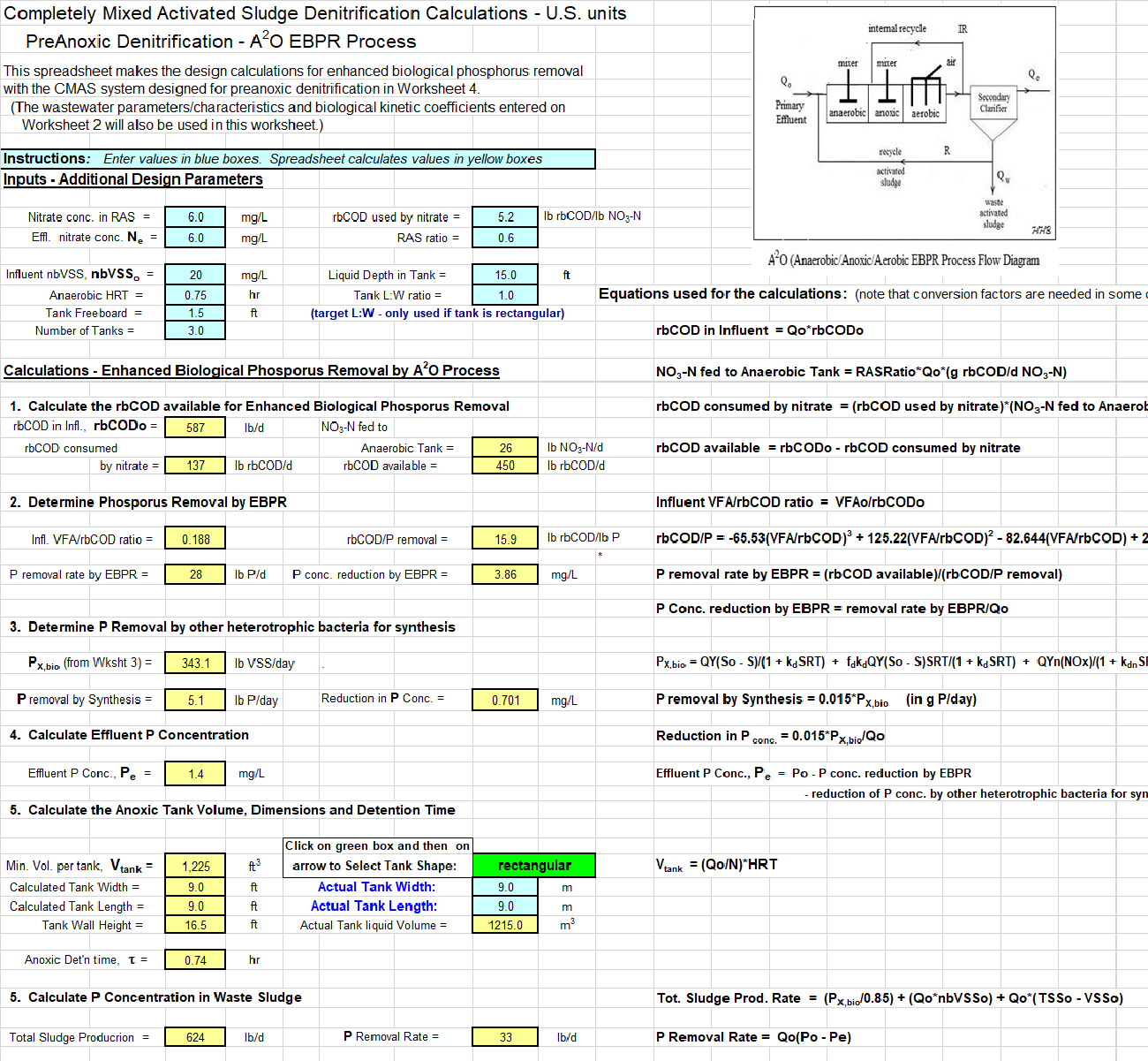

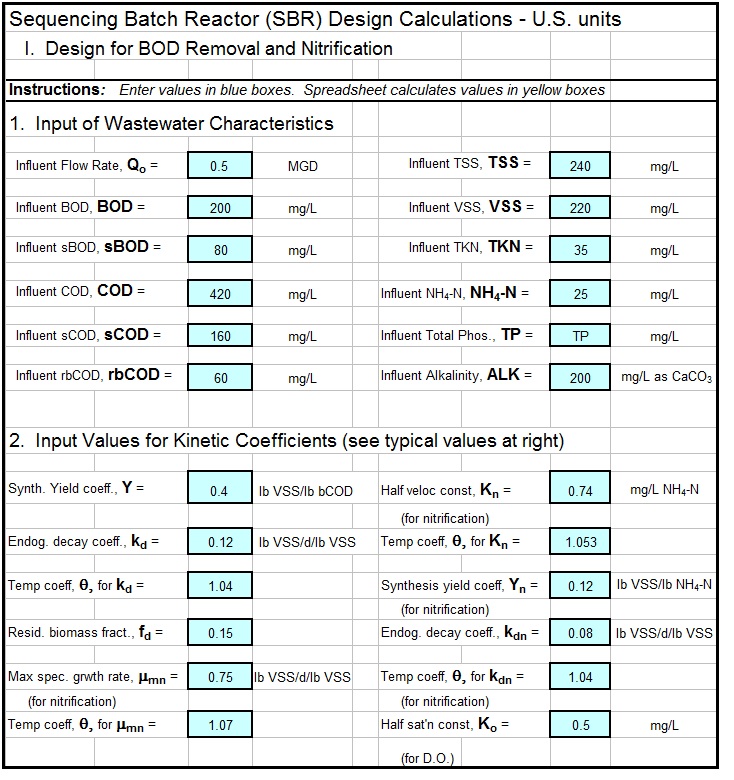

Bioreactor Design Calculations, Mass transport limitations inherent in the axial-flow bioreactor design are illustrated with model calculations. An example membrane bioreactor wastewater treatment calculations spreadsheet is partially shown in the image below. Chemical reaction engineering is the synthesis of all these factors with the aim of properly designing a chemical reactor. Continuous flow bioreactors- Gas-liquid mass transfer in bioreactors concept of K L a and its measurement aeration.

Design And Performance Of Single Use Stirred Tank Bioreactors Bioprocess Internationalbioprocess International From bioprocessintl.com

Design And Performance Of Single Use Stirred Tank Bioreactors Bioprocess Internationalbioprocess International From bioprocessintl.com

The performance of any bioreactor depends on many functions such as those listed below. Reactor design uses information knowledge and experience from a variety of areas-thermodynamics chemical kinetics fluid mechanics heat transfer mass transfer and economics. Design calculation26 Table 3-2 Parameter used for methane production and energy conversion 27 Table 3-3 Parameter used for wall thickness calculation. In the upper left part the parameters can be found.

Reactor design uses information knowledge and experience from a variety of areas-thermodynamics chemical kinetics fluid mechanics heat transfer mass transfer and economics.

Read another article:

X NA0 NA X FA0 FA Batch Flow. In searching for the optimum it is not just the cost of the reactor that must be minimized. Design of the reactor is no routine matter and many alternatives can be proposed for a process. Free Online Courses From The Worlds Leading Experts Since 2007. One design may have low reactor cost but the materials leaving the unit.

Source: engineeringexcelspreadsheets.com

Source: engineeringexcelspreadsheets.com

This review intends to provide an inclusive package of the engineering parameters together with their calculation procedure in addition to the modeling techniques in TE bioreactors. Biomass concentration Nutrient supply. Reactor volume V meter3 barrel UK barrel US dry barrel US federal barrel US liquid barrel US oil petroleum bushel UK bushel US dry centimeter3 cord firewood cord foot wood cup Canada cup metric cup US deciliter decimeter3 foot3 gallon UK gallon US liquid inch3 kilometer3 liter milliliter millimeter3 ounce UK fluid ounce US fluid pint UK pint US quart UK quart US stere. Therefore are three different parts available in the application. Denitrification Archives Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets.

Source: sciencedirect.com

Source: sciencedirect.com

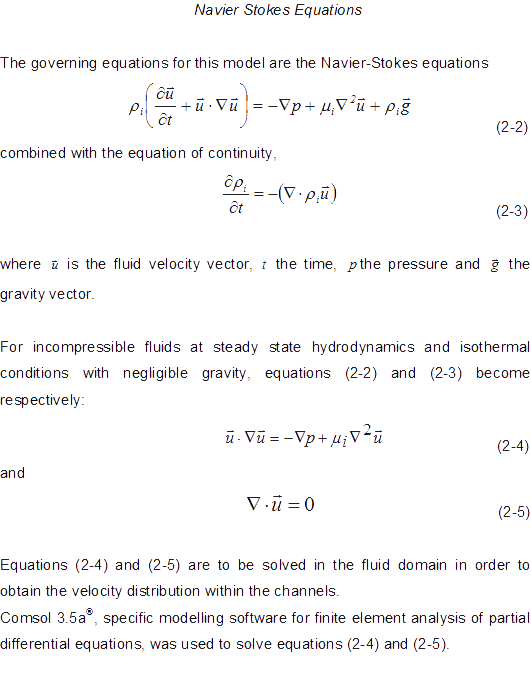

Of agitators Z x rho D Z - reaction mass height rho - density D - inner dia of reactorvessel. Q V Q SU Q BR 17 kW 88 kW 258 kW. 37 The general operation of a BAL device is such that hepatocytes are seeded in the. However CO 2 stripping in the growth phase is often inadequate. Airlift Reactor An Overview Sciencedirect Topics.

A01 X For batch reactors conversion is a function of time whereas for flow reactors at steady state it is a functionofvolume 222 CSTRDesignEquation Using the expression for the. Bioreactor scale-up is a critical step in the production of therapeutic proteins such as monoclonal antibodies MAbs. Such an approach requires excellent bioprocess mechanical production and control engineering along with ergonomic considerations to ensure easy assembly and efficient operation of the equipment. In the upper left part the parameters can be found. 2.

Source: proteinseniordesign.weebly.com

Source: proteinseniordesign.weebly.com

A01 X For batch reactors conversion is a function of time whereas for flow reactors at steady state it is a functionofvolume 222 CSTRDesignEquation Using the expression for the. In de lower part is a spreadsheet section where the results of the calculations are shown. Design of the reactor is no routine matter and many alternatives can be proposed for a process. Mass transport limitations inherent in the axial-flow bioreactor design are illustrated with model calculations. Decision Matrices And Calculations Protech Designing The Next Large Scale Bioreactor.

Source: slideplayer.com

Source: slideplayer.com

Design of the reactor is no routine matter and many alternatives can be proposed for a process. Therefore are three different parts available in the application. The first consideration in the design of this bioreactor was to apply systems-engineering principles to ensure robust and reliable performance. D a d C a c B a b A The basis of calculation is most always the limiting reactant. Bioreactors Engineering Ppt Download.

Source: 2010.igem.org

Source: 2010.igem.org

Therefore are three different parts available in the application. Free Online Courses From The Worlds Leading Experts Since 2007. F A F A0 - Rate of moles A fed x moles A reacted moles A fed F A F A0 -. Ad Learn Suitable Criteria For The Scale-Up Of Bioprocesses Mass And Heat Transfer. Team Ucl London Fermenter Mechanics 2010 Igem Org.

Source: bioprocessintl.com

Source: bioprocessintl.com

In order to design such a fixed bed reactor it is necessary to be able to predict the temperature and concentration at every point in the reactor since present design methods are based on the numerical integration of basic differential equations which can be derived from material and energy balances over a differential element of the bed. With this program you can design different kinds of bioreactors. Design of the reactor is no routine matter and many alternatives can be proposed for a process. The size of fermentors ranges from 1-2 litre laboratory fementors to 500000 litre or occasionally even more fermentors of upto 12 million litres have been used. Design And Performance Of Single Use Stirred Tank Bioreactors Bioprocess Internationalbioprocess International.

Source: 2010.igem.org

Source: 2010.igem.org

F A F A0 - Rate of moles A fed x moles A reacted moles A fed F A F A0 -. Ad Learn Suitable Criteria For The Scale-Up Of Bioprocesses Mass And Heat Transfer. Rate of Moles of A leaving F A Rate of Moles of A fed - Rate of Moles of A reacted. Biomass concentration Nutrient supply. Team Ucl London Fermenter Mechanics 2010 Igem Org.

Source: aiche.org

Source: aiche.org

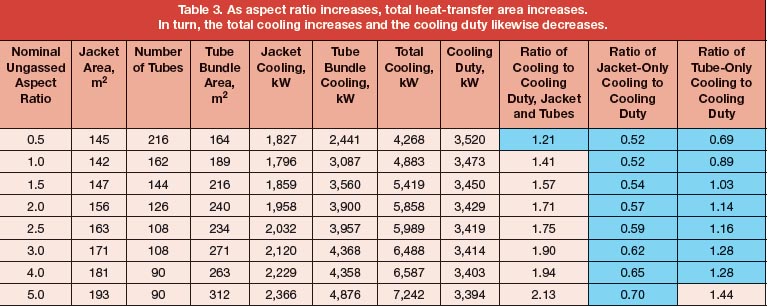

Rate of Moles of A leaving F A Rate of Moles of A fed - Rate of Moles of A reacted. Mass transport limitations inherent in the axial-flow bioreactor design are illustrated with model calculations. Q BR k BR A BR ϑ BR 05 Wm 2. C 250 m 2 70 C 88 kW Necessary heat. Optimize Aspect Ratio In Industrial Fermenters Aiche.

Source: websites.umich.edu

Source: websites.umich.edu

In de lower part is a spreadsheet section where the results of the calculations are shown. Bioreactors are important inevitable part of any tissue engineering TE strategy as they aid the construction of three-dimensional functional tissues. The bioreactor is the heart of any biochemical process in which enzymes microbial mam-malian or plant cell systems are used for manufacture of a wide range of useful biological products. Figure 2-11 Up-flow anaerobic sludge blanket reactor. Plug Flow Reactors Pfrs.

Source: engineeringexcelspreadsheets.com

Source: engineeringexcelspreadsheets.com

Ad Learn Suitable Criteria For The Scale-Up Of Bioprocesses Mass And Heat Transfer. CONVERSION AND REACTOR SIZING 1. Batch reactor- calculation of batch time quantitative evaluation of batch processes sources of non-ideality. An example membrane bioreactor wastewater treatment calculations spreadsheet is partially shown in the image below. Denitrification Archives Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheets.

Source: 2010.igem.org

Source: 2010.igem.org

Free Online Courses From The Worlds Leading Experts Since 2007. Therefore are three different parts available in the application. C 250 m 2 70 C 88 kW Necessary heat. The performance of any bioreactor depends on many functions such as those listed below. Team Ucl London Fermenter Mechanics 2010 Igem Org.

Source: sciencedirect.com

Source: sciencedirect.com

In the upper right part the designed bioreactor is shown. CONVERSION AND REACTOR SIZING 1. Free Online Courses From The Worlds Leading Experts Since 2007. Rate of Moles of A leaving F A Rate of Moles of A fed - Rate of Moles of A reacted. Bioreactors An Overview Sciencedirect Topics.

Source: slideplayer.com

Source: slideplayer.com

The design parameters for an ideal bioreactor include reduction of mass transfer resistances and elimination of substrate limitations so that the device can function at maximum efficiency and minimize the dead volume within the device thereby reducing the effects of plasma dilution in the patient. Q BR k BR A BR ϑ BR 05 Wm 2. Rate of Moles of A leaving F A Rate of Moles of A fed - Rate of Moles of A reacted. Power number 05 as per agitator curves Power Np x x N3 x d5 05 x 1500 x 60603 x 165 786284 watts 1054 HP Considering losses which might occur due to transmission gland losses coupling losses they would. Bioreactors Engineering Ppt Download.

Source: goodreads.com

Source: goodreads.com

Bioreactor scale-up is a critical step in the production of therapeutic proteins such as monoclonal antibodies MAbs. Bioreactors are so designed that they provide the best possible growth and biosynthesis for industrially important cultures and allow ease of manipulation for all operations. In de lower part is a spreadsheet section where the results of the calculations are shown. In order to design such a fixed bed reactor it is necessary to be able to predict the temperature and concentration at every point in the reactor since present design methods are based on the numerical integration of basic differential equations which can be derived from material and energy balances over a differential element of the bed. Spreadsheets For Mbr Wastewater Treatment Process Design Calculations By Harlan H Bengtson.