22 Bituminous macadam BM shall consist of mineral aggregate and appropriate binder mixed in a hot mix plant and laid with a. The bitumen mix that is densely graded has continuous gradation say in the proximity of maximum density line. Bitumen sand mix design.

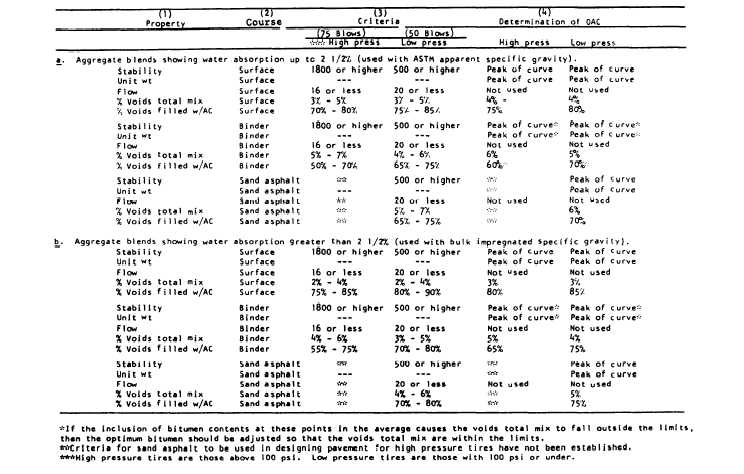

Bitumen Sand Mix Design, It is compacted with 75 blows of a rammer of weight 454kg with a. Design Methods Asphalt Mix 7th Edition MS-2 Asphalt Mix Design Methods 7th Edition. Grading-2 is suitable for layer thickness of 50 mm to 75 mm and 265 mm nominal size of aggregate shall be used. Reference code and specification.

Aggregate Gradation Of Asphalt Mixture And Sand Mastic To Measure Download Table From researchgate.net

Aggregate Gradation Of Asphalt Mixture And Sand Mastic To Measure Download Table From researchgate.net

When the mix lack materials of two or more sizes it will form gap graded bitumen mix. Determine the specific gravity of each compacted specimen. Mixing 41 Plot a graph of bitumen viscosity against temperature. The bitumen mix that is densely graded has continuous gradation say in the proximity of maximum density line.

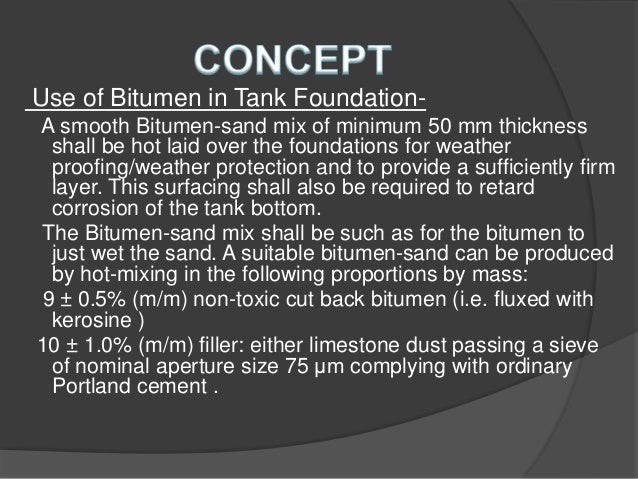

The mix design of our tank foundation mastic includes filler grit bitumen and cementitious components that are mixed with carefully selected crusher sands and binders to make a ready to use continuous bitumen sand mixture cushion for tank foundations and pipe protection layers.

Read another article:

The aim was to develop a new HMA design method for South Africa. This group of material is produced using either sand fines Type F or crushed rock Type C they are all design mixtures although mix stability is not normally specified. One of the widespread use of bitumen is in the pavement design and construction. Bitumen content by mass of total mix 45 minimum. Sand will form open graded bitumen mix.

Source: yumpu.com

Source: yumpu.com

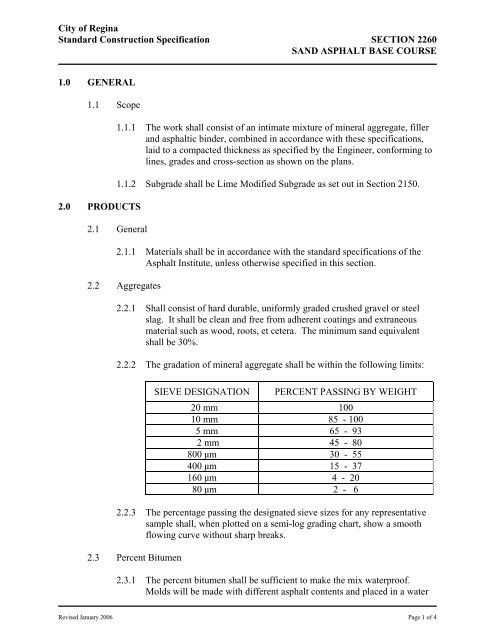

The mix is uniformly blended and poured into a standard cylindrical mould 102 mm diameter and 64 mm depth heated to 93-149C. The aim of the authors was to complete the knowledge on the modulus resistance to fatigue and creep of three sand-bitumens corresponding to categories b c and d. There are mainly two stages of mix design in bringing a bituminous pavement. Techniques of optimising the sand type and content in the mix are also developed and guidelines for desired aggregate structures for. Sand Asphalt Base Course City Of Regina.

Source: slideplayer.com

Source: slideplayer.com

It can consist of processing gravels. Determine the proportion of each aggregate required to produce the design grading. All agencies concerned with pavement design and construction. The aim was to develop a new HMA design method for South Africa. Module 4 Asphalt Mix Design Ppt Video Online Download.

Source: researchgate.net

Source: researchgate.net

Grading-2 is suitable for layer thickness of 50 mm to 75 mm and 265 mm nominal size of aggregate shall be used. The mix is uniformly blended and poured into a standard cylindrical mould 102 mm diameter and 64 mm depth heated to 93-149C. The normal grade of bitumen 100150 however other grades are available. This group of material is produced using either sand fines Type F or crushed rock Type C they are all design mixtures although mix stability is not normally specified. Mix Design Properties For Purc Bituminous Concrete Download Table.

Source: pavementmaterials.co.za

Source: pavementmaterials.co.za

The quantity of bitumen by weight of the mix is measured and poured into the heated aggregate. It can consist of processing gravels. SAND-BITUMEN MIXTURES - MODERN MIX-DESIGN FORMULA AND APPLICATION TO PAVEMENT DESIGN LES SABLES-BITUMES - FORMULATION MODERNE ET APPLICATION AU DIMENSIONNEMENT. From the graph determine the temperatures for mixing and compaction taking into account the viscosity requirements stipulated in Table 1. Bitumen Sand Tank Foundation Mastic Supplier South Africa Pavement Materials Group.

Source: eng-tips.com

Source: eng-tips.com

Materials CA Crushed stone FA Coarse sand FA Foundry sand MF Fine sand Binder Bitumen Specific Gravity 279 246 263 260 102 21. The aim was to develop a new HMA design method for South Africa. When the mix lack materials of two or more sizes it will form gap graded bitumen mix. The spatial composition of a cold foamed bitumen mix. Slab Mat Foundation Storage Tank Engineering Eng Tips.

The normal grade of bitumen 100150 however other grades are available. Bitumen-sand setting bed material. Determine the proportion of each aggregate required to produce the design grading. Mix Design The objective of the study is to make a comparative study of asphalt mixes with partial replacement of fine aggregate. Bitumen Sand Mix For Tank Foundations Bs 2654 Pdf Pdf.

Source: engineeringtraining.tpub.com

Source: engineeringtraining.tpub.com

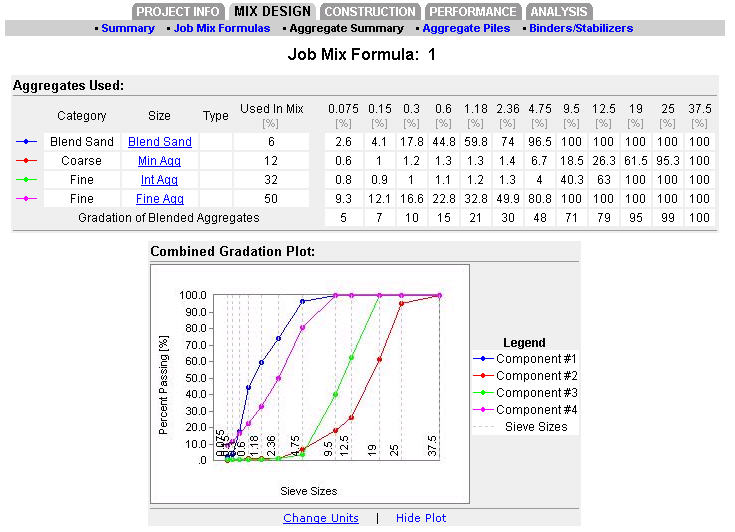

Bulk specific gravity of materials used in bituminous mix. The mix is uniformly blended and poured into a standard cylindrical mould 102 mm diameter and 64 mm depth heated to 93-149C. The quantity of bitumen by weight of the mix is measured and poured into the heated aggregate. It is compacted with 75 blows of a rammer of weight 454kg with a. Job Mix Formula Ac Mixes.

Source: researchgate.net

Source: researchgate.net

Laboratory Mix Design of Cold Bitumen Emulsion. Bitumen content by mass of total mix 45 minimum. BITUMINOUS MIX DESIGN AND SUPERPAVE MIXES BY CHANDRA SEKHAR PASUPULETI BTechCIVIL 2 Objective To understand What are the mix design methods. Standard bitumen emulsions is a brown liquid and contain 40 to 75 bitumen 01 to 25 emulsifier 25 to 60 water plus some minor componentsin this research work bitumen emulsion of slow setting-1 grade SS-1 taken as binder for cold mix designthese emulsion tested on laboratory before making cold mix specimen for design mix in table no03 shown the parameters and testing. Aggregate Mixing Ratio For Wearing Course Download Table.

Source: researchgate.net

Source: researchgate.net

On Bituminous Mix Design Animesh Das 1 Abstract. 1 minuteA pre-planned bituminous mix design for pavement construction helps in producing a mix that is workable durable strong and economical in nature. Bitumen-sand setting bed material. RDGN022 Mix Design of Bituminous Materials Page 3 of 3. Mix Design For A Typical Cold In Place Asphalt Recycling Project Download Table.

Source: pavementinteractive.org

Source: pavementinteractive.org

RDGN022 Mix Design of Bituminous Materials Page 3 of 3. The normal grade of bitumen 100150 however other grades are available. Techniques of optimising the sand type and content in the mix are also developed and guidelines for desired aggregate structures for. The mix is uniformly blended and poured into a standard cylindrical mould 102 mm diameter and 64 mm depth heated to 93-149C. Superpave Mix Design Pavement Interactive.

Source: pavementinteractive.org

Source: pavementinteractive.org

Mixing 41 Plot a graph of bitumen viscosity against temperature. Mix Design The objective of the study is to make a comparative study of asphalt mixes with partial replacement of fine aggregate. Mix design considerations for cold and half-warm bituminous mixes with emphasis of foamed bitumen. Limitations of Marshall method Superpave mixes Importance of other methods 3 Mix design Objective. Superpave Mix Design Pavement Interactive.

Source: researchgate.net

Source: researchgate.net

The bitumen mix that is densely graded has continuous gradation say in the proximity of maximum density line. Design Methods Asphalt Mix 7th Edition MS-2 Asphalt Mix Design Methods 7th Edition. Control joints and drain holes are covered with geotextile. This article briefly discusses. Bitumen 60 70 Specification Download Table.

Source: slideshare.net

Source: slideshare.net

Bituminous mix design 241 Overview The bituminous mix design aims to determine the proportion of bitumen ller ne aggregates and coarse aggregates to produce a mix which is workable strong durable and economical. Bitumen content by mass of total mix 45 minimum. Bitumen content by mass of total mix 4 minimum 2 DBM Grading-2. The design and use of porous asphalt mixes CD only Appropriate standards for the use of sand asphalt Guidelines for the design manufacture and construction of bitumen rubber asphalt wearing courses Sealing of active cracks in road pavements ETBs The design and use of emulsion treated bases Hot mix paving in adverse weather. Use Of Bitumen In Tank Foundation And As A Joint Filling Material.

Source: mdpi.com

Source: mdpi.com

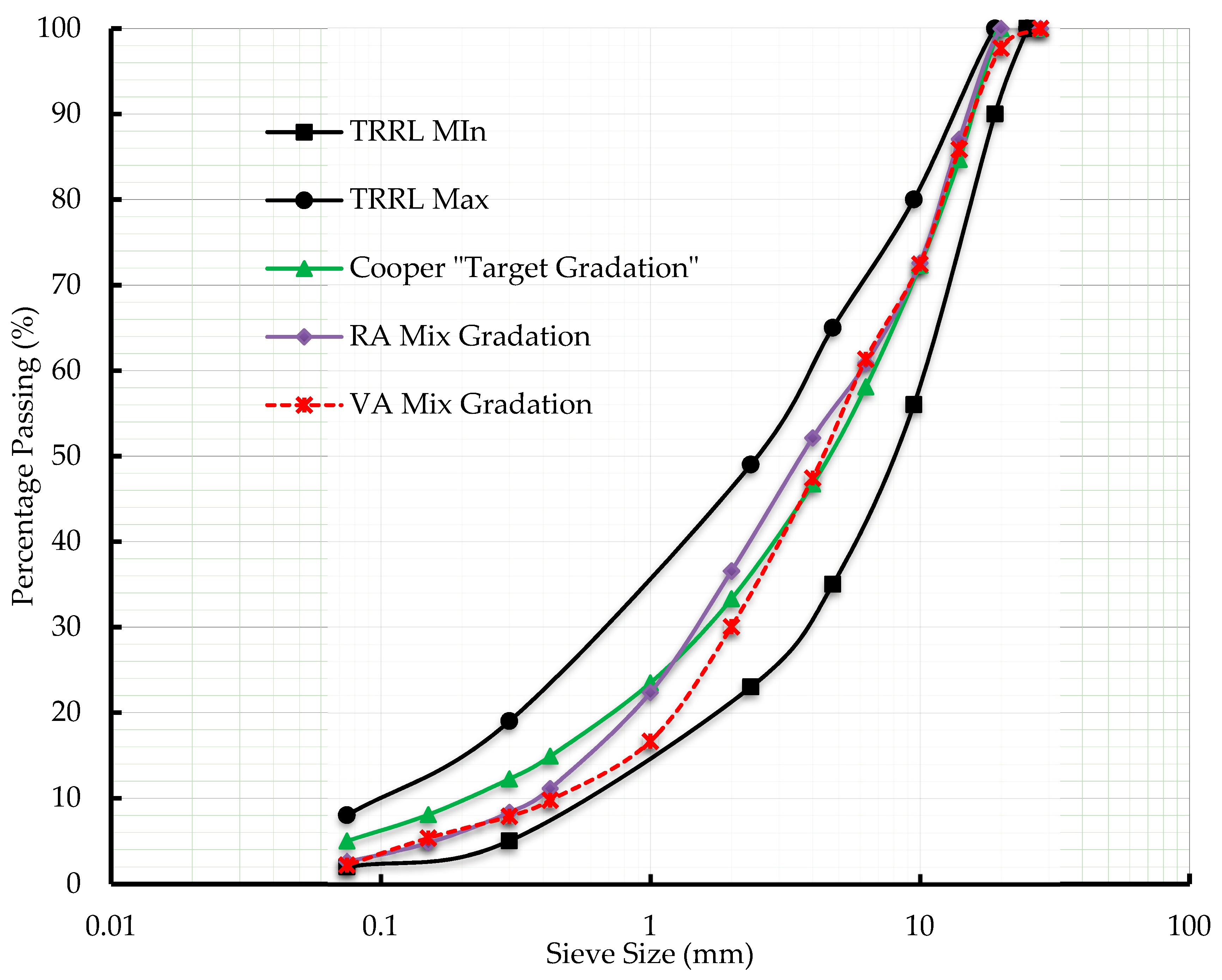

Mixing 41 Plot a graph of bitumen viscosity against temperature. The bitumen mix with a large amount of fine aggregate ie. 21 This specification deals with the basic outline for the design construction and controls needed while laying bituminous macadam course for highways. 9 7 8 1 9 3 4 1 5 4 7 0 0 ISBN 978-1-934154-70-0 AI-14103 AsphaltMixCoverFinalindd 1 123014 1221 PM. Buildings Free Full Text Laboratory Mix Design Of Cold Bitumen Emulsion Mixtures Incorporating Reclaimed Asphalt And Virgin Aggregates Html.

Source: chegg.com

Source: chegg.com

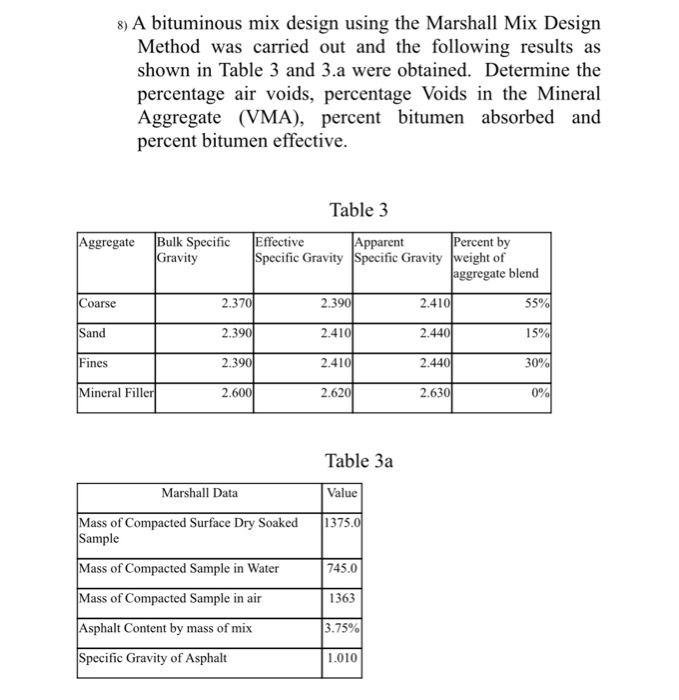

Bitumen-sand setting bed material. From the graph determine the temperatures for mixing and compaction taking into account the viscosity requirements stipulated in Table 1. Mixing 41 Plot a graph of bitumen viscosity against temperature. The requirements of the mix design and the two major stages of the mix design ie dry mix design and wet mix design will be. Solved 8 A Bituminous Mix Design Using The Marshall Mix Chegg Com.